Precision quality Machining

The turnkey source for all your manufacturing requirements

Providing CNC Machining Turnkey Solutions Since 2003

Quality Conforms to AS 9100 and ISO 9001

All equipment is on a calibration schedule in addition to checking against gages before use and in process to ensure confidence in our quality. All components go through final inspection before being sent to customers.

Mitutoyo CRT-AV 574, Tesa Micro Hite, Delta Optical Comparator, height gages and surface plates at all machine stations, Gage blocks, Gage pins, Bore micrometers, Surface tester, Various Special micrometers for grooves and undercut.

What We Do

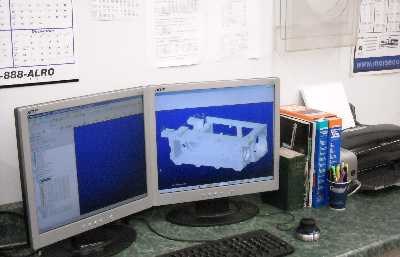

Complete Manufacturing

At PQM we can provide all phases of manufacturing from prototype, to short run projects and large volume production runs. We offer a complete facility of manual and CNC equipment to meet your needs.

Engineering & Design

PQM uses advanced SOLIDWORKS software to assist you in final design to accommodate tolerance and geometry for best fit, form and function of our customer’s parts.

Precision CNC Machining

PQM utilizes the latest Mastercam CAD/CAM software to assist us for part programming providing the highest quality components at the most affordable prices.

Aerospace & Defense

Laser Application

Power Generation

Fiber Optics

Firearms

Commercial

Who We Are

Experience

PQM has over 50 combined years experience in extended mechanical and technical background to help resolve engineering and development application issues.

Quality

Our manufacturing, inspection and quality control processes conform to AS 9100 and ISO 9001 specifications.

Philosophy

PQM was founded on the most basic principles of good business and doing what we say we will do.

Work With Us

Machining and Manufacturing Experts since 2003

Precision Quality Machining was founded on the most basic principles of good business with the belief that by doing what we say we can will earn the respect and loyalty of those customers seeking our services.